Power Flame Incorporated – Small to Medium Ultra Low NOx Gas Burners from USA.

An innovative and forward thinking force in the commercial combustion equipment industry, Power Flame Incorporated manufactures gas, oil, combination gas/oil, low NOx burners and combustion control systems. Designed for Commercial, Industrial and Process Applications, each one of Power Flame’s products share environmentally conscious designs and are crafted from quality materials by expert staff of dedicated professionals.

Flexibility of choice in NOx reduction techniques is the key to successful emissions control. Combustion chamber geometry and construction, as well as heat release levels are among the more important determining factors in the choice of low NOx application equipment. Heat exchanger designs vary significantly, and the choice of the most appropriate NOx reduction method is an essential element in meeting current and future emissions standards. The Power Flame NOVA concept provides U.L. listed, factory tested packages capable of using a wide range of NOx reduction techniques.

Power Flame engineering will tailor a low emissions burner system to your specific job requirements to provide optimum choice of the most cost effective protocols for your application. Years of dependable performance from hundreds of NOVA system applications have produced NOx reductions in excess of 60% on gas and 40% on oil. The NOVA concept gives you the power of choice. The NOVA concept employs a modular approach for each NOx reduction technique. All Power Flame burners can be field retrofitted by adding the appropriate low NOx module kit to the existing system.

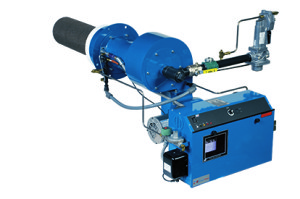

Power Flame UCMAX 9ppm Ultra Low NOx Burner.

The Cmax Burner offers state-of-the-art technology for maximum combustion efficiency and operating performance when firing all types of light oils and gaseous fuels. Designed specifically for today’s firetube boilers, the Cmax burner utilizes a unique firing head design which provides stable combustion over a wide turndown range (10:1 on gas and 8:1 on air atomized oil). Available in multiple sizes (CM9 thru CM14), the burners have a minimum rating of 1,260 MBH and a maximum rating of 92,400 MBH (2200 BHP). Available in a low NOx version utilizing induced flue gas recirculation, the burner provides minimal emissions on gas or oil. The easy access door on the blast tube allows convenient maintenance of the firing head components without disturbing either the fuel piping or electrical connections. The bottom or top-entry gas manifold connection facilitates left or right hand configurations. Modular design concept produces added flexibility for a wide range of optional features. For more information, Click Here.

Power Flame NOVA Plus 9 to 12ppm Ultra Low NOx Burner.